As options for lighting have expanded, so has the terminology. For example, those who recently have remodeled a room or installed a new lighting system undoubtedly have heard of LED tape and strips. However, their lighting technician may not completely have explained how lights are installed with precision, and so they are left wondering, What are LED profiles?

As options for lighting have expanded, so has the terminology. For example, those who recently have remodeled a room or installed a new lighting system undoubtedly have heard of LED tape and strips. However, their lighting technician may not completely have explained how lights are installed with precision, and so they are left wondering, What are LED profiles?

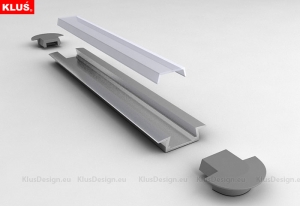

LED profiles, otherwise known as extrusions, are aluminum channels that house the lighting tape. The terms can be used interchangeably to describe casings that will fit snugly into the grooves in ceilings, walls, closets, floors, cabinets, and stairs. The profiles allow you to place LED lights exactly where they are intended without having to resort to obtrusive and bulky hardware.

In addition to guiding and positioning LED strips, profiles also will help prevent contact damage. They are not waterproof, but they can help prevent the intrusion of moisture and thus extend the life of the light strip.

LED Profile Style Options

Profiles are designed in a variety of configurations to fit most any situation and offer different advantages. The selection is so vast, most of those who are considering changes to their lighting pattern likely will need the help of a professional to select just the right extrusion.

The type and depth of the profile will depend on where the lighting will be placed and the effect it is intended to present when it is finally installed. Profiles are specially designed to house lighting that is to be installed on drywall or ceilings. They can be angled or glass edged. They also can be heavy duty and rugged for pavement and sidewalk use, or combined with an optic lens to narrow and extend the reach of the light. There even are LED floor lamps built using extrusions.

Profile Installation Options

There are two primary ways to install LED profiles. Many can be fixed into place with the application of counter sink screws that are driven directly into the profile. For some applications, it may be preferable to install them using fixing brackets. The brackets are put in place first. Then the profile can simply be snapped into place, which will leave them with a clean, sleek look.